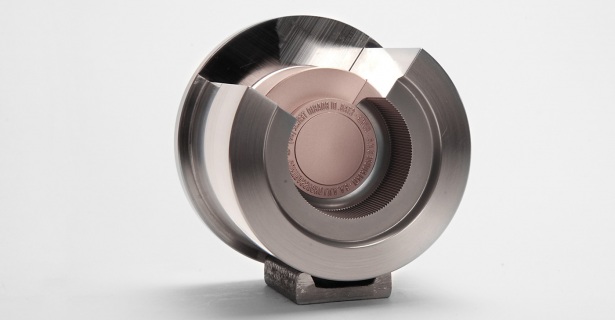

DIES FOR BEVERAGE CAPS

We have been manufacturing dies with different mouldings for over 30 years, such as the PCO 1810 and the PCO 1881 for the beverage industry. We are your ideal partner for the manufacture of beverage cap dies. The number of mouldings, designs, dimensions and quantities varies from customer to customer, and is constantly adapted to the rapidly growing market.

Advantages of cold hobbing

Thanks to the cold hobbing process and the corresponding quality controls, we are able to produce these dies for you in next to no time with a superior surface quality and without any reworking. All our dies boast precise dimensions and exact geometry, as well as a longer service life, by adapting to the flow of the grain structure.

Different types of material

The cold-hobbed dies are pressed with the greatest of accuracy in various types of material according to the customer’s request: "1.2083, 1.4034, 1.2341 or 1.2343". After they have been pressed, all the dies are machined for a uniform countersinking depth and are trued up.

Dies for beverage caps

WHERE QUALITY SETS STANDARDS

We have been producing dies with different mouldings for over 30 years, such as the PCO 1810 and PCO 1881 for the beverage industry, as well as dies for general caps. Thanks to the cold hobbing process, we can manufacture these dies for you in next to no time with a high surface quality and without any reworking. All our dies boast precise dimensions, exact geometry and an extended service life.