DIES / MOULD INSERTS

We have been a competent partner within the industry for over 30 years with our manufacture of dies / mould inserts for cold hobbing processes (CHP). All our dies boast precise dimensions, exact geometry and an extended service life.

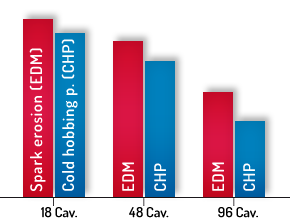

COLD HOBBING NOT EDM

Reduce your costs with the cold hobbing process (CHP). We can reduce your production costs simply by using a tool with 18 cavities. This process gives all our dies a superior surface quality and durability, so there is no need for any reworking (additional costs).

WHERE QUALITY SETS STANDARDS

We have been producing dies with different mouldings for over 30 years, such as the PCO 1810 and PCO 1881 for the beverage industry, as well as dies for general caps. Thanks to the cold hobbing process, we can manufacture these dies for you in next to no time with a high surface quality and without any reworking. All our dies boast precise dimensions, exact geometry and an extended service life.